In Practice: Making and Tuning Gongs with Hazemann & Monnin

Kwan Ann Tan

The sonnerie au passage, or chiming jump hour, is an unusual pairing of complications rarely seen across watchmaking. Hazemann and Monnin’s Montre École Souscription watches join the ranks of a select few, numbered alongside modern watches such as the AKRIVIA Tourbillon Chiming Hour AK-03 and the Patek Philippe Chiming Jump Hour reference 5275. Developed within a nine-month timeframe as an academic project, the pair focused on simplifying and streamlining what can often be a complex piece of work.

Broadly speaking, chiming watches can be divided into repeaters and sonnerie categories. The former will provide the time at the push of a button or the touch of a slider, while sonnerie watches typically chime automatically at specific intervals of time. The Montre École Souscription watches fall into the latter category, chiming once every hour.

The hammer, which strikes the gong that encircles the watch to create the chime.

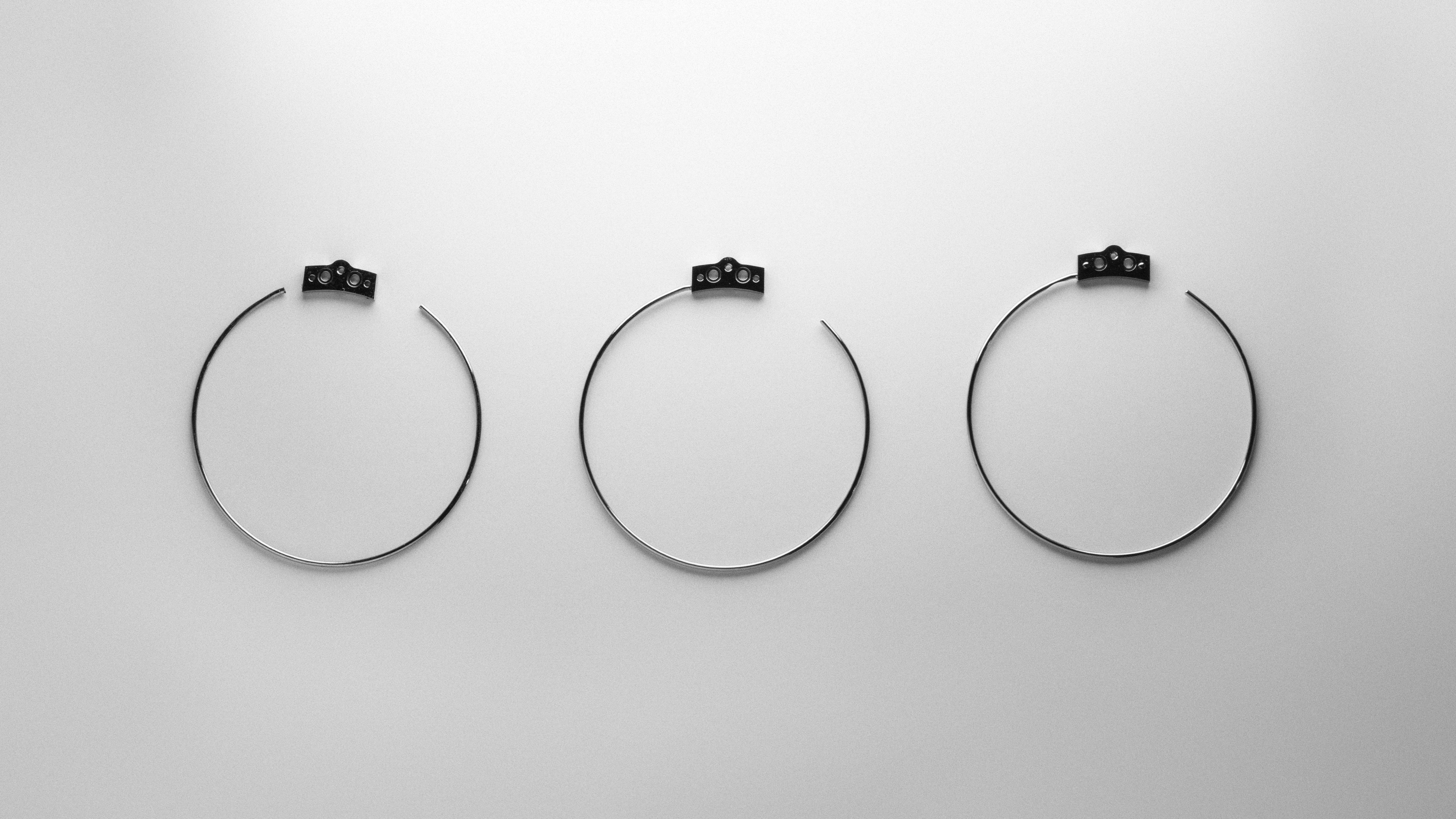

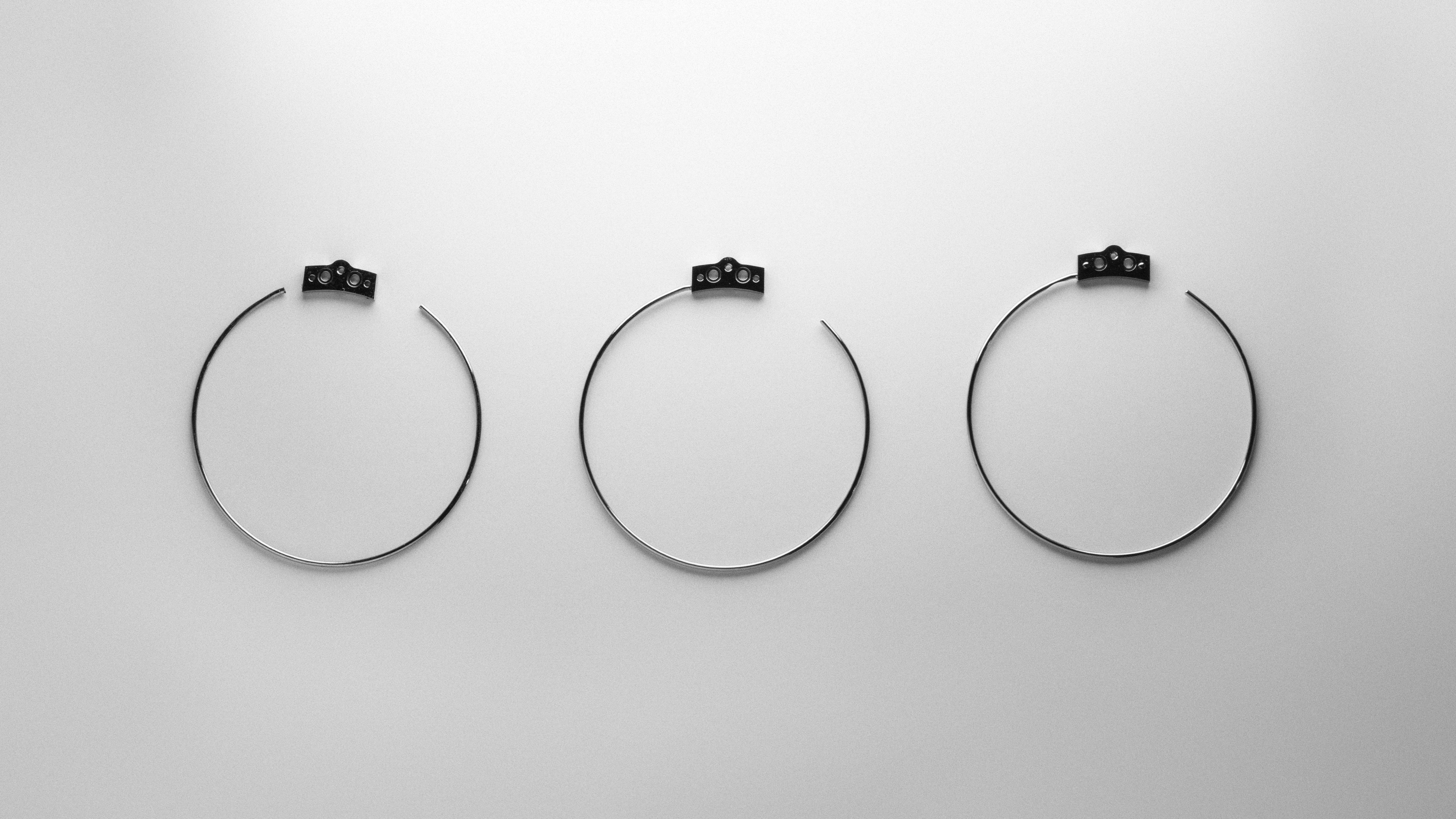

This occurs when a gong is struck within the watch – a thin, circular piece of metal that encircles the outer section of the watch. The resonance of this gong causes a vibration and produces a single chime on the change of the hour. According to Hazemann & Monnin, these are typically made of very hard, tempered steel, although more advanced techniques can also manufacture these gongs in sapphire.

The Montre École Souscription watches feature a single component at the centre of the watch which performs multiple functions. This central snell wheel is referred to as the “grande bascule” by the pair. According to Hazemann & Monnin, “It accumulates energy by arming the striking hammer, and then releases the tension when the cam drops, once per hour.” This strikes the gong, producing a “clear and resonant sound that lasts around 3 to 4 seconds.”

“We had to experiment many times to find the ideal shape that would produce the desired sound — the tuning of the gong is adjusted by the ear of the watchmaker.”

The Tools

The methods of creating these gongs differ through the years. Hazemann & Monnin explain how these have been created in the past: “Traditionally, gongs are made in two parts, joined by a soldering process called ‘brazing’, located between the base and the start of the wire. The wire’s diameter can vary depending on the desired sound, as can its length, which is often maximized based on the available space inside the watch.”

Bringing this into modern day, however, they also explain that a new method of manufacturing was introduced in the 1990s, which allowed for monobloc gongs — which are created in a single piece — to be created, and this greatly reduced vibration losses in sound transmission.

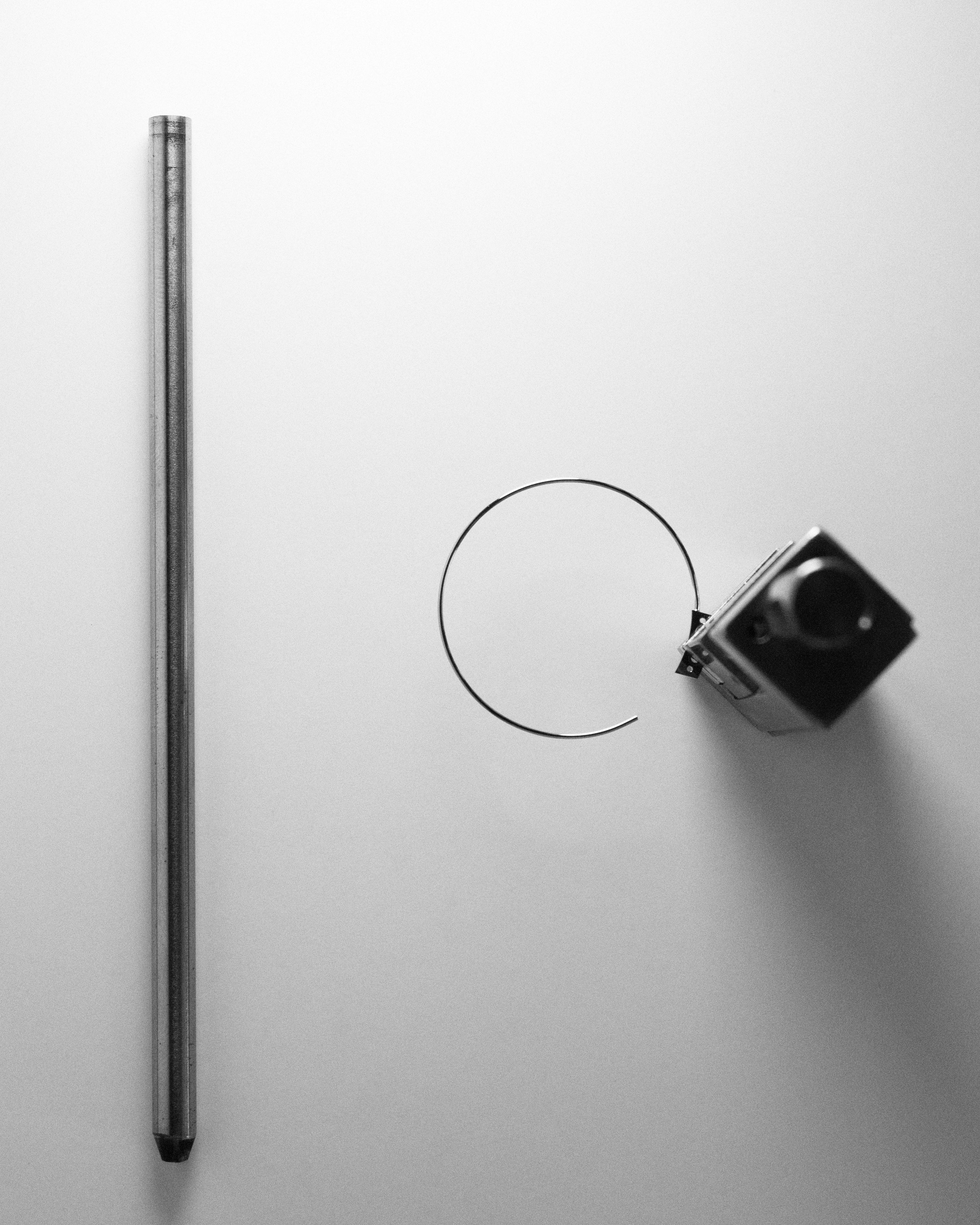

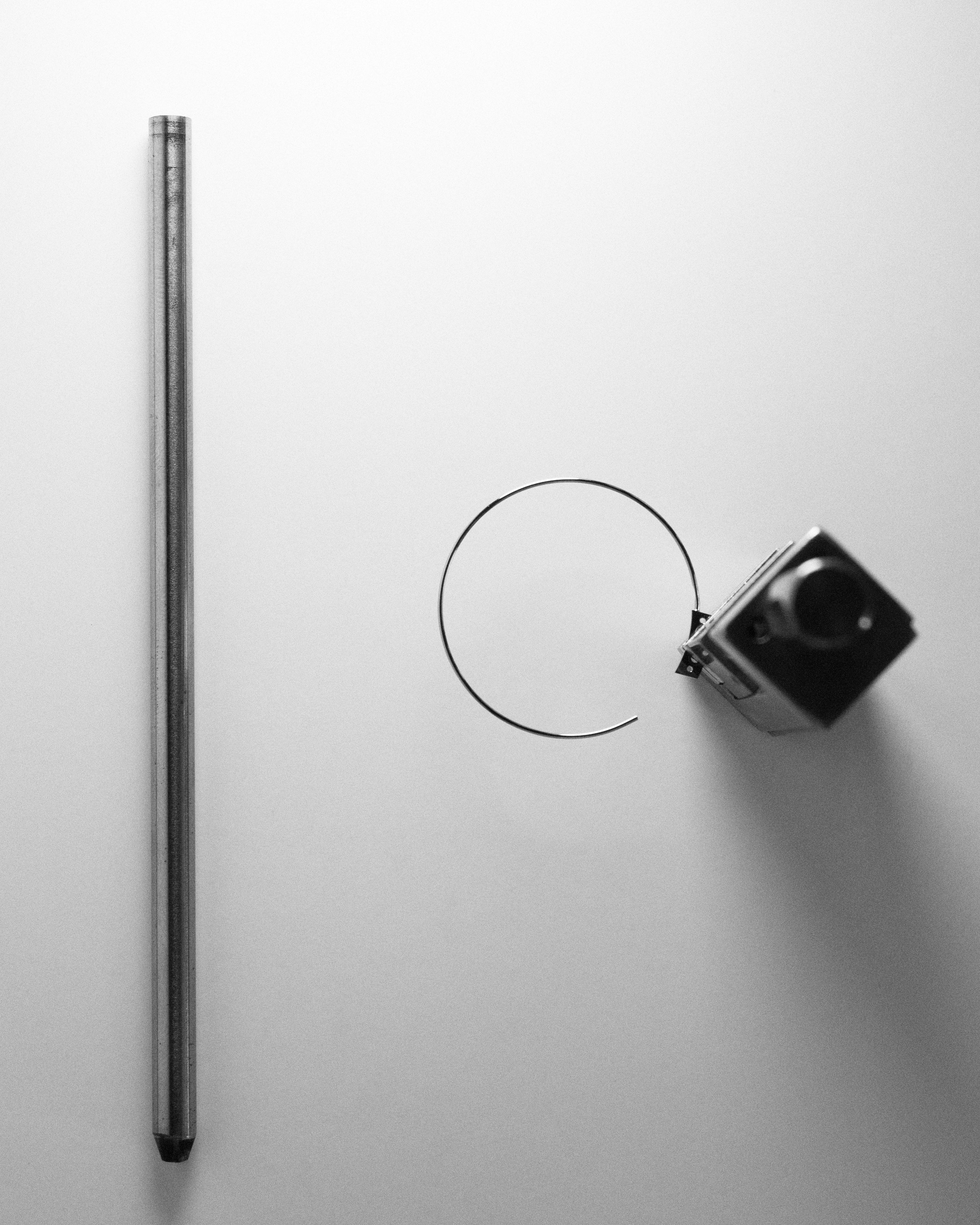

So how are the gongs for the Montre École Souscription watches created today? The process itself is a guarded secret, but Hazemann & Monnin were able to share a few details with us. “We know that the raw material starts as a steel bar, which is then turned to the required diameter, and milled at the base to create various fixing elements (pins, screws),” After these crucial features are built into the material’s form, “the gong is placed into complex molds to achieve its final form and required geometry.”

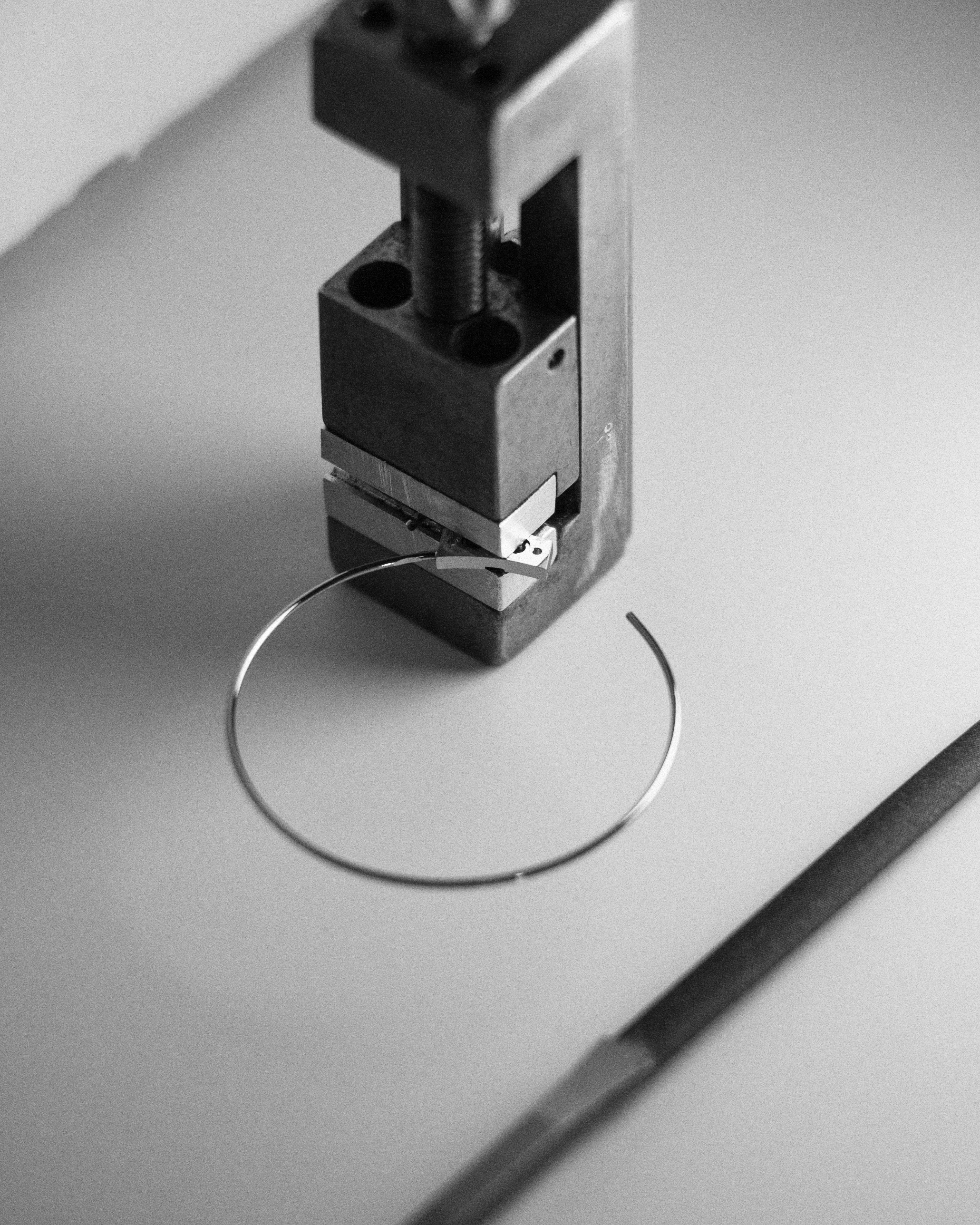

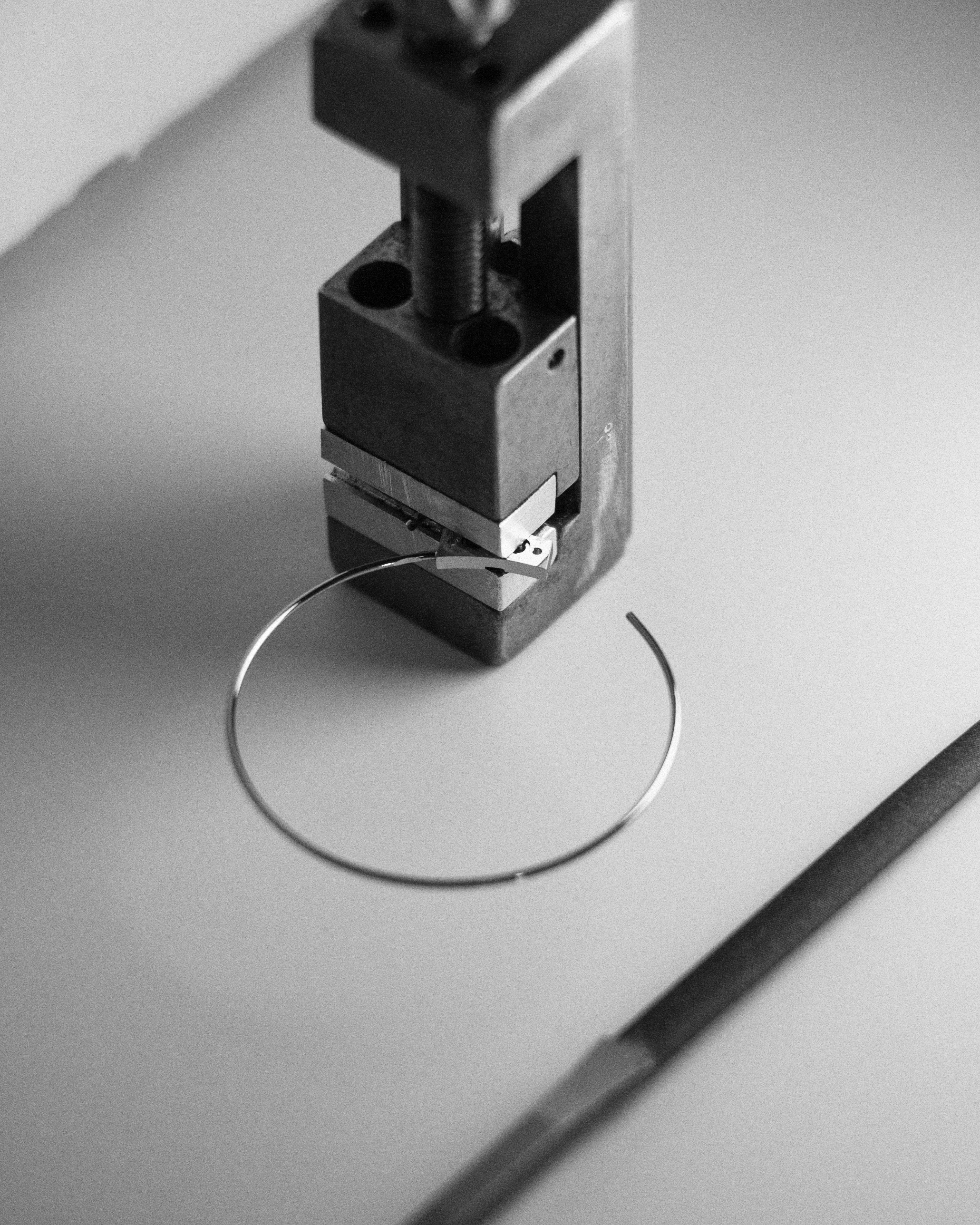

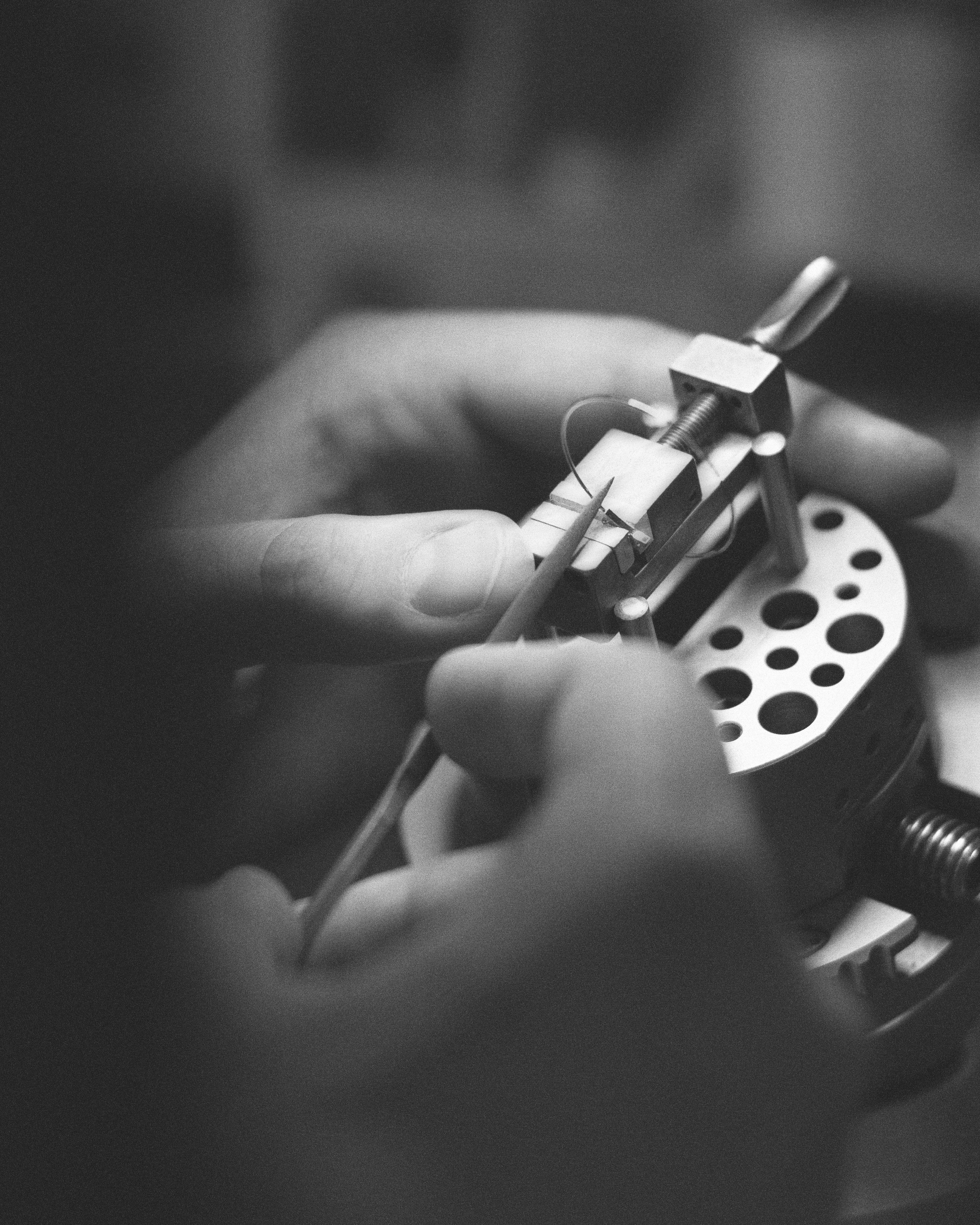

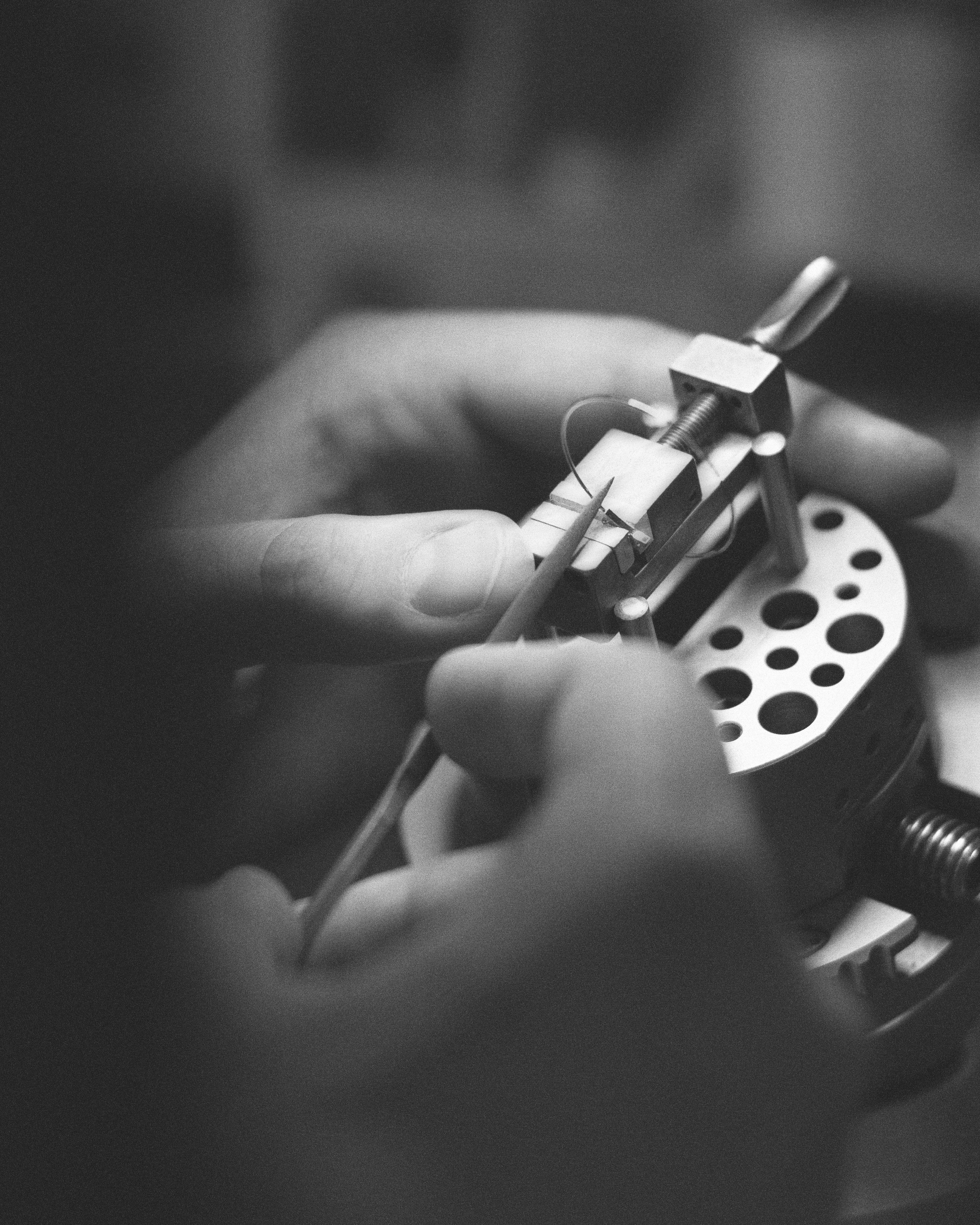

The tools used to assist in filing the gongs – a file and a clamp to hold it in place.

The final step is the most personal and variable of the process, as the watchmaker works on the gong at the bench, tuning it directly and completing the polishing. At Hazemann & Monnin’s workshop, their gongs are filed by hand just before the point which would strike the case, a very delicate process that can make or break the entire component, as the hardness of the material makes it extremely fragile.

The sound of the chime can be varied through the length of the gong, as well as where the hammer strikes it. Hazemann & Monnin share that the “ideal” gong should be tuned as closely as possible to the musical note A at 440 Hz, which is also the international standard for musical pitch, and what most orchestras tune to.

“We had to experiment many times to find the ideal shape that would produce the desired sound,” Hazemann & Monnin explain. “The tuning of the gong is adjusted by the ear of the watchmaker, but it can also be measured with advanced equipment used in major manufactures such as Patek Philippe.”

Understandably, the shape and individual qualities of how the gong has been created and filed can create variations of sound between watches. In the Montre École Souscription, several aspects have also been calculated to produce the desired sound — the case features hollow oblongs throughout to allow the sound to resonate and travel more efficiently, and there are key details that remain a secret for now.

Each gong and the sound it produces is the result of feel and touch, tuned specifically by the watchmaker.

As the pair note, “It is always a balance between aesthetics and technical performance. The watchmaker must therefore optimize the space and the shape of the gong to get as close as possible to their ideal note.”

Our thanks to Alexandre Hazemann, Victor Monnin, and their team for sharing the process of creating their watches with us.